National Depression Glass Association

Preserving America's Glass Manufacturing Heritage

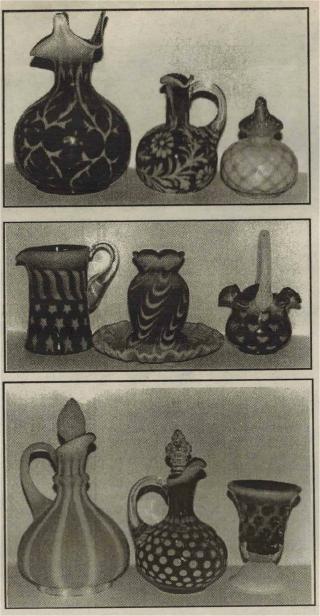

Spot Moulds used by Fenton

by Carrie Domitz

From the Daze, August 1996

The Fenton Art Glass Co. began using spot molds in 1910. The Belmont Glass Co. and Hobbs Brockunier Co. pioneered the use of this type of mold in the late 1880s. They were followed by many others such as Northwood, Dugan-Diamond. Beaumont and Model Flint. The early production of the spot mold items by the Fentons was not a reproduction but was simply their version of a glass that was currently being made by many other companies.

A spot mold is used to produce an optic in a piece of

blown glass. Fenton used this type of mold to produce

Coin Spot, Drapery and Button & Braids water sets

from 1910 to 1920. The colors produced were green

opalescent, blue opalescent and flint opalescent. Amethyst opalescent was being produced during those

same years and rare examples of the water sets have

turned up in this color.

Coin Spot, Drapery and Button & Braids water sets

from 1910 to 1920. The colors produced were green

opalescent, blue opalescent and flint opalescent. Amethyst opalescent was being produced during those

same years and rare examples of the water sets have

turned up in this color.

During the 1920s, lemonade sets, night sets and vases in the Drapery pattern were produced in a special line and color called Victorian Topaz. It was both opalescent and iridescent. It is very rare today and examples sell for premium prices. A line of bathroom sets, night sets and lemonade sets were produced in colors called Victorian green, Victorian blue and cameo. These colors were green, blue or amber [brown] opalescent. The optic was a swirl or a straight optic.

Cranberry opalescent wasn't made by Fenton until the late 1930s. A 1938 catalog shows a few pieces in the Swirl pattern. Flint opalescent [later changed to French opalescent] was produced in many spot molds such as Block optic, swirl, stripe, wide stripe, ring and coinspot. Many of those patterns are very rare today.

Sy Wright approached the Fentons about this same time. He had purchased a warehouse full of moulds which had been used by the Dugan Diamond Glass Company. Over the years, Fenton produced glass for L.G. Wright in a variety of patterns and colors. Some of those patterns include Daisy and Fern, Stars and Stripes, Honeycomb, Eye Dot, Christmas Snowflake and Swirl. Fenton was the only company to produce this type of glass for L.G. Wright.

Coin Dot appears in the 1947 Fenton catalog. it was produced in cranberry, blue, lime, topaz and French opalescent. This pattern was so successful that it was made for many years and it is rare to not see an example of it at a antique show (often labeled Victorian glass). There is a lot of confusion between Coin Dot and Coin Spot. A Coin Dot piece will be mostly opalescent with a circle of clear color. Coin Spot will be predominately clear with opalescent spots.

The 1953 catalog introduced several new spot mold optics. Swirled Feather is the most popular now but also introduced were: Fern, Diamond Quilt, Rib and Ring (the last two were part of the New World line). Spanish Lace was to have been added to the line that year but Mr. Wright asked the Fentons not to use that pattern because it was one of the spot molds he owned and might want to use in the future. They changed their plans and tried Seaweed instead. Only a few items in this pattern were made and all would be very rare today.

The 1953 catalog also includes information as to how coin dot was made. I will use both that information and the information given to me by Frank Fenton to try to describe the process.

First a gather of glass is attached to the blow pipe. If that gather is cranberry or lime color it is coated with a layer of clear glass containing bone ash. It is then dropped into a spot mold which gives it the pattern. It is removed from that mold and is chilled with a blast of cool air. That blast is carefully timed by the worker so that when the desired effect is achieved that time can be used for the entire production. This is a difficult step and many undesirable pieces are broken before the best effect is achieved. After the glass is chilled it is put back into the glory hole and reheated. This reheating causes the raised pattern to tum white or "strike." The reheated glass is blown into a shape mold to achieve the final product.

Not all spot molded glass is opalescent. Transparent colors are also given a pattern by using a spot mold such as diamond optic. Optic molds have also been used for opaque glass. Northwood made a group of pieces in their Chinese coral and opaque blue using a diamond optic. These pieces must be held to the light in order to see their pattern. Fenton's rosalene color has been produced using many different optic molds. Rosalene is a heat sensitive glass so once the piece has been struck the pattern is easy to see.

Fenton's Cranberry Opalescent glass is so popular that collectors are often willing to pay much more for a rare piece of Fenton's Cranberry than a Victorian glass collector is willing to pay for an older piece. That fact speaks volumes for the popularity of Fenton Glass.

Webmaster's NOTE: This article was taken from the August 1996 edition of the Daze. The author, Carrie Domitz, is an avid collector, dealer and researcher of Fenton Art Glass Company. She was a regular contributor to the Daze during its time of publication.